What is RPE and Where is it Used?

Respiratory Protective Equipment (RPE) is a form of Personal Protective Equipment (PPE) that is commonly used in Australian workplaces to protect the wearer from a range of airborne contaminants.

Various forms of RPE are available in Australia, some of which are required by Law to be worn in certain workplaces and industries. This includes both half and full-face respirator devices, as well as Regulation Breathing Protection such as P1 and P2 dust masks.

It is important to comply with the following Australian Standards when purchasing and maintaining RPE in Australia:

- AS/NZS 1716-2012 Respiratory Protective Devices

- AS/NZS 1715-2009 Selection, Use and Maintenance of Respiratory Protective Equipment

Common Types of RPE

The two main types of respirators include:

- Air-purifying respirators - These purify the external air that is breathed in by the wearer, using either natural breathing or a powered fan to draw in air.

- Supplied-air respirators - These respirators supply clean air from a source (such as from a tank) and are used when the natural air is immediately dangerous to the wearer, or where oxygen levels are low.

Two forms of Air-purifying respirators include:

- Negative Pressure Respirators - Negative Pressure Respirators are most common in Australian workplaces and will provide protection against a lesser level of air contamination than Positive Pressure Respirators.

- Positive Pressure Respirators

Negative Pressure Respirators are available to suit various levels of air contamination:

Depending on the substances found in the workplace or area, different levels of protection will be required. The more contaminated the workplace air, the more protective the respirator needs to be. It is also essential to provide an appropriate filter.

The Two types of Respirator Filters are:

1. Particulate Filters

Particulate filters will protect only against solid and liquid particles and will be ineffective against gasses and vapours.

Particulate filter classification has three levels that, from lowest to highest, are P1, P2 and P3 (example below).

2. Gas/Vapours Filters

Gas/Vapour filters provide protection against numerous levels of vapours and gasses found in a work area. Gas and vapour filters do not protect against particles.

Classification for determining absorption capacity, from lowest to highest, is as follows: Class AUS, Class 1, Class 2 and Class 3. It is important to select a protection Class that is adequate to absorb the level of contamination in the air.

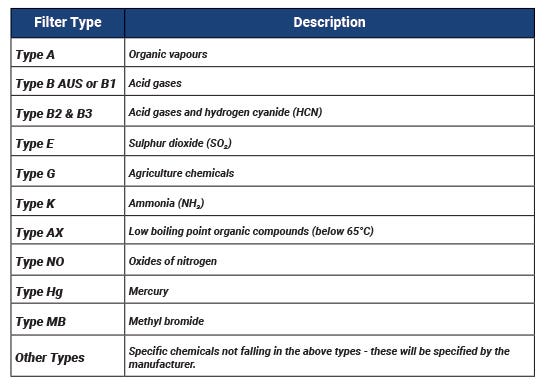

In addition, Gas/Vapour filters will also be labelled with a letter rating that depicts the type of gas or vapour that a filter will protect against. It is important to select a respirator filter Type that matches the contaminants present.

In certain cases, it is possible to purchase combined filters that protect against numerous gases and vapours. These will be indicated on the box when purchasing.

DID YOU KNOW? Even when not in use, Gas/Vapour respirator filters will continue to absorb airborne contaminants.

Remember to store RPE filters in airtight bags or containers between each use. This will decrease filter maintenance and replacement costs.

Three additional factors to consider when selecting RPE

1. The Worker

- Face shape and size will influence the size and model of respirator appropriate for each wearer. The effectiveness of any respirator is determined by the fit of the device to the wearers face. One type and size will not suit everyone so it is extremely important to carry out regular fit tests for every employee.

- Facial hair including sideburns, stubble, beards, moustaches etc. may prevent respirators from adequately sealing. Ensure that all workers are clean-shaven when wearing a respirator.

- Other considerations such as any pre-existing medical conditions (e.g. lung disease, asthma, cancer etc.) and psychological conditions must also be recognised.

2. The Environment

- Factors such as heat and humidity of a work environment will affect the appropriateness of certain respirators.

- NOTE: Certain respirators, (e.g. powered air-purifying respirators) may act as an ignition source when exposed to flammable or explosive vapours, gases and dusts. It is important to be aware of these factors when choosing a respirator.

- The more contaminated the workplace air, the more protective the respirator needs to be. As such, knowing the level of air contamination in the workplace is important when choosing the type of respirator. In some work situations, it is possible for the level of harmful airborne contaminants to exceed the capability of the respirator - this is known to be harmful to the wearer.

3. The Task

- A respirator must be chosen based on it's capacity to match the physical demands of the task and intended length of wear.

- Matching filter Types and Classifications to the work task and any expected risks is also important.

- Keep in mind the various other PPE that will be worn by a worker, and how these will interfere with the effectiveness or wearability of the respirator.

- Depending on vision and communication requirements, certain respirators may be more or less appropriate.

Fit Testing Methods

Fit-tests are important for all forms of Respirators. This includes disposable and reusable respirators. If it hasn't been fit tested - it's not accepted in Australia.

Fit testing detects if air is able to leak into the respirator through gaps in the seal between the wearer's face and the respirator facepiece. Fit-testing may be carried out by a competent person, manufacturer, supplier or service provider.

Two methods of fit testing include:

- Qualitative fit testing - a pass/fail test that relies on the wearer’s ability to taste or smell a specific test agent. This type of test can be used only on half-face respirators and may not be entirely accurate.

- Quantitative fit testing – Measures air leaks in the respirator with specialised equipment. This type of test can be used on both half-face and full-face respirators and is the most reliable of the two options.

Fit-testing should be carried out regularly, at least once per year for each worker or every time a new respirator is used. Should the wearer's facial features or characteristics change (for example, due to injury, weight changes or other factors), a new fit test must also be performed.

It is the responsibility of the PCBU to keep a written record of all fit tests carried out for each individual worker. This record should log the following information:

- The method of test performed.

- The respirator tested (including make, model, style and size)

- The test date and time.

- The accurate result of the test.

Handy Tips for RPE Maintenance

Regular checking and subsequent replacement or maintenance of the following respirators is required.

Disposable respirators

- Disposable respirators must be disposed of after one use.

- Ongoing maintenance is not required but replacement is mandatory.

Re-usable respirators

- Inspect the respirator before and after each use and during cleaning.

- Replace all parts that are cracked, torn, broken, missing or worn.

- Follow the manufacturer's instructions.

Facepieces

- Check for any holes or tears, no matter how small.

- Check the face seal is not broken or distorted.

- Clean and/or disinfect according to the manufacturer’s instructions.

Head straps and harness

- Check the webbing for breaks and frayed edges - replace if found.

- Measure elasticity and check fit.

Inhalation and exhalation valves

- Check for tears, cracks or distortions - replace if found.

- Check the valve and valve seat for dust, dirt and hair - clean or replace if found.

Filters

- Know the service life of a filter.

- Replace filters before the end of the specified service life.

- Ensure a filter is properly secured and the filter housing is not cross-threaded.

- Replace a particulate filter when it becomes difficult to breathe through.

- Check for visible damages or dirt and replace immediately. Gas and vapour filters have a certain capacity for removing gases or vapours from the air. Once this capacity is reached, gas or vapour will pass straight through and provide no protection to the wearer.