It's time to know watt's up with electrical safety in your workplace.

Working with electricity can be dangerous. Across Australia and New Zealand, an average of 20.5 fatal incidents involving electricity occur each year (based on findings between 2000 and 2018). Non-fatal electrical incidents are also common in workplaces and may cause varying degrees of shock and/or harm to the individual. Electrical incidents can cause both internal and external harm, and may leave permanent damage. With proper safety precautions and a better general understanding of the dangers associated with electricity work, it is possible to reduce these statistics considerably.

In which profession are workers likely to come into contact with electricity?

Electricians, engineers, and a range of various trade workers deal directly with electricity every day. Such work may involve electrical installation, circuit assembly or work on overhead power lines. Generally, workers in these professions are well equipped to deal with the dangers of electric work and thus the fatalities in these industries are relatively low (despite the continuous occurrence of freak incidents).

On the other hand, farmers, construction workers and even office workers are known to work with electricity in a more indirect sense. The risk of exposure to electrical hazards in these situations are still prevalent. In fact, they are often more common as these professionals are unlikely to have appropriate electrical training.

What are a few common hazards to watch out for in or near the workplace?

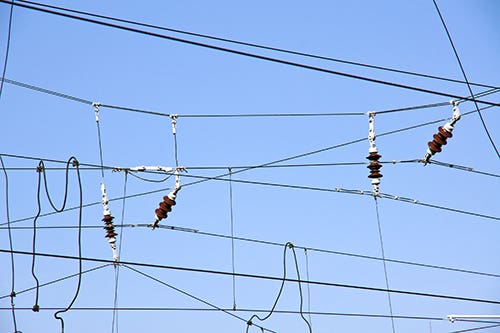

Overhead Power Lines

Overhead powered and energized electrical lines have high voltages which are known to cause electrocution and bodily injury including but not limited to severe burns. As a general rule, it is recommended to maintain a minimum of 3 metres from all overhead power lines and any related equipment. In the workplace, it is important to utilise appropriate safety equipment such as barriers and signage. These measures warn nearby non-electrical workers of the hazards present in that area.

Damaged Tools and Equipment

Exposure to such electrical equipment can be extremely dangerous, even fatal. It is recommended that the use of damaged electrical tools and equipment be banned in every workplace. To ensure against accidental use of damaged items, all employees must be thoroughly trained to check for cracks, cuts or abrasions on cables, cords or wires. If a product is faulty, it should be immediately repaired by a professional or safely discarded.

Wet Conditions

Water, rain or any form of moisture can increase the risk of electrocution as it is a conductor. If the item, tool or equipment is damaged, this risk increases. For this reason, it is recommended not to operate tools or equipment in any environment that has been recently wet/moist, is currently wet/moist, or may be wet/moist in the near future. If any electrical equipment has been wet or moist, it should be inspected by a qualified electrician before it is used.

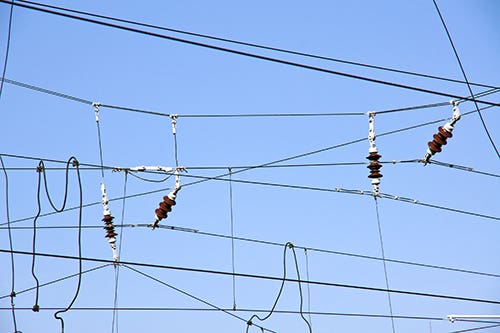

Exposed Electrical Parts

Contact with exposed electrical parts can cause electrocution, shocks and even burns. Examples of such electrical hazards include temporary lighting (example in image above), open units for power distribution, and electrical cords with detached or frayed insulation parts (coating around wires). It is recommended that a qualified electrician confirm the safety of these parts or repair where necessary, and secure any exposed electrical chords.

Inadequate Wiring, Incomplete Grounding and Overloaded Circuits

It can be difficult to identify issues with electrical wiring, grounding or circuits without extensive knowledge in the industry. For this reason, it is important to ensure that all electrical installations are completed by a reputable electrician. This will decrease the likelihood of faulty installation and lack of grounding. In addition, it is beneficial to conduct regular fire risk assessment and other general risk assessments in every workplace. If a workplace uses a lot of electrical equipment or is considering doing so, it is important that the workplace health and safety manager (or related title) become familiar is electrical safety and related Australian Standards.

General recommendations for decreasing risk of electrical incidents in the workplace.

-

Ensure only appropriately licensed or registered electricians carry out electrical work

-

Switch off electricity where possible before working on equipment

-

Check electrical regularly before use, to ensure it is not damaged.

-

Perform an assessment of the electrical safety risks in the workplace.

-

Know the relevant Electrical Australian Standards required for the individual workplace.

-

Use battery operated tools rather than mains power tools where possible.

-

Remove damaged, unsafe electrical equipment or cords from the work site or office.

-

Do not overload power sockets. Where necessary, use a power board rather than an adaptor.